Most Commercial and Industrial gate owners are unaware of the standards of automatic gates and how they need to be installed. ADG employ strict safety standards to specifies the performance requirements in regard to the safety in use for any type of power operated doors, gates and barriers installed in areas in the reach of persons, and for which the main intended uses are giving safe access for goods and vehicles accompanied or driven by persons industrial, commercial or residential premises.

Introduction

The purpose of this page is to assist those who have any responsibility for the specification, design, manufacture, purchase, installation, maintenance, inspection or use of automatic gates. Automatic / electric gates can injure and kill. In recent years a number of children from around the world including New Zealand and Australia have been fatally injured by automatic gate.

Hazards and Controls

When identifying hazards and danger zones associated with automatic gates, you should consider, among other things, the following:

- any points where persons may be injured by being crushed or becoming trapped, for example:

- meeting point between swing gates when closing,

- sliding gate at “end of travel” positions,

- trapping of feet between lower edge of gate and ground,

- space between a moving gate and a fixed object, and

- contact with moving parts at the drive unit;

- hazards from being caught or hooked by sharp edges or projections;

- the impact forces produced by a gate when it strikes a person or an obstacle;

- hazards associated with the gates being activated automatically, or by another person (for example, by a sensor / loop under the road surface activating a gate when a car drives over it, a remote button, a remote control pressed by a third party or a gate operated by dialling a mobile phone);

- the possibility of gates becoming detached from their supports and falling over;

- all danger zones up to a height of 2.5m should be identified;

- and electrical hazards, such as electric shock or erratic behaviour due to ingress of moisture on electrical circuits.

Increased Risk

Factors that can give rise to an increased risk include:

- use by children,

- use by elderly people,

- unrestricted access or other instances when it is not possible to instruct, train or supervise the gate users,

- high frequency of use or large number of people passing by, or a high degree of automation.

Generally, a perimeter gate, where the public may be present as users or passing by, will require the highest level of safety provision.

Sliding / Cantilever Gates

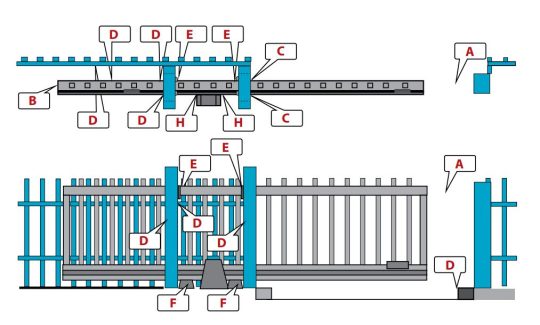

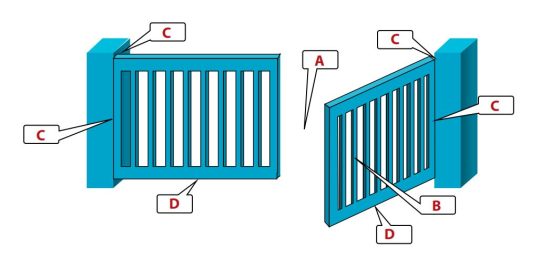

The opposing images show a plan and elevation view of a cantilever / sliding gate. Areas A to H show the areas where injury could potentially be caused. The bullet points A to H describe these hazards and the type of measures needed to control the risk from each hazard.

A

Main closing edge: crush and impact hazards controlled by either inherent force control, safety edges, light/radar curtaining or by having the gate hold-to-run.

Force-control can be provided by intelligent drive units that cause the gate to reverse when an obstruction is sensed.

Safety edges are sensitive rubber switching strips which, when contact is detected, send a signal to the gate controller to reverse the movement of the gate.

Beam curtaining means placing a curtain of light or radar in front of the danger areas. If the curtain is breached while the gate is operating, the gate will reverse its direction. This may be installed to give protection to vehicles primarily but it will also prevent inadvertent contact with pedestrians.

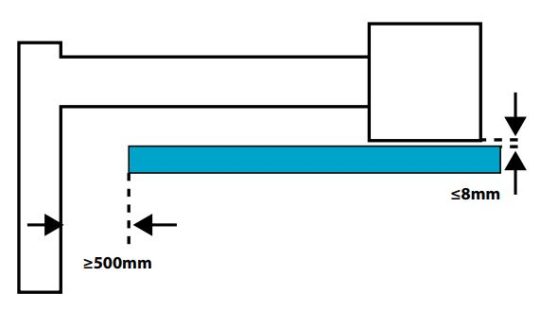

B

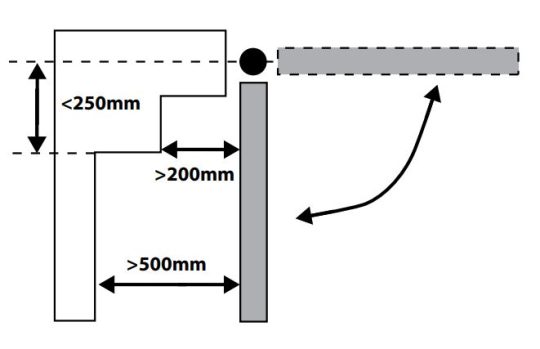

Main opening edge: crush and impact hazards (crush hazard exists whenever a leaf closes to within 500mm of a fixed object, impact hazards are present throughout movement) controlled by either:

- Guarding

- Safety distances

- Inherent or safety edge derived limitation of forces

- Beam curtaining

E

Upper guide/roller draw in hazards controlled by either:

- Guarding

- Beam curtaining

F

Lower cantilever gate rolling gear hazards controlled by either:

- Lower edge slot for internal rollers

- Guarding for external or exposed rollers

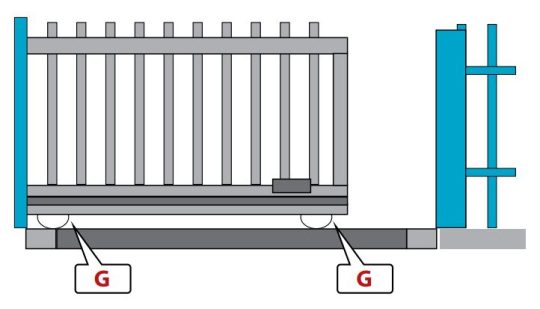

G

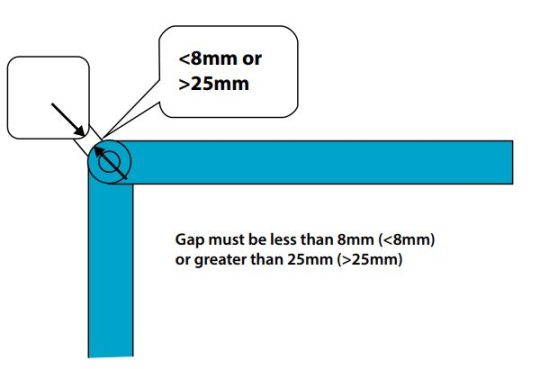

Lower tracked gate rolling gear hazards controlled by:

- Guard to within 8mm of ground

H

Drive unit draw in hazards controlled by:

- Guard

C

Entrance portal support frame:

- Safety distances

- Safety Edges

- Beam curtaining

D

Lower edge shear and crush hazards controlled by either:

- Safe distances in combination with inherent limitation of force

- Safety edges on both sides of lower opening edge

- Beam curtaining

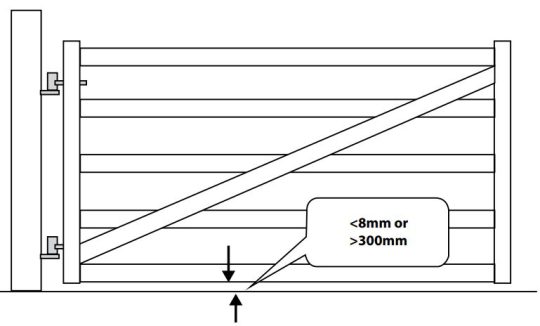

Swinging / Hinged Gates

Hinged gates have some similar hazards to sliding gates. However, the fact that the gates swing open and closed presents some other hazards that must also be considered.

A

Main closing edge crush and impact hazards controlled by either:

Photoelectric / Safety Photocell beams on the closed face in combination with inherent or safety edges or limitation of forces

Beam curtaining

B

Opening crush and impact hazards controlled by either: (Opening crush hazards exist wherever a leaf opens to within 500mm of a fixed object, impact hazards are present throughout movement)

- Safety distances for the crush element only

- Inherent or safety edge derived limitation of forces

- Beam curtaining

C

Hinge area crush, draw in or shear hazards controlled by:

- Safety design hinges

- Guards

- Safety Edges

- Beam curtaining

D

All other support frame, leaf or perimeter: shear and draw in hazards controlled by either:

- Guarding

- Safety Edges

- Beam curtaining

Note:

This list is not exhaustive, other examples may exist dependant on design detail. Nonetheless, all hazards must be revealed by assessment and controlled.